33+ Cement Plant Equipment Condition Monitoring

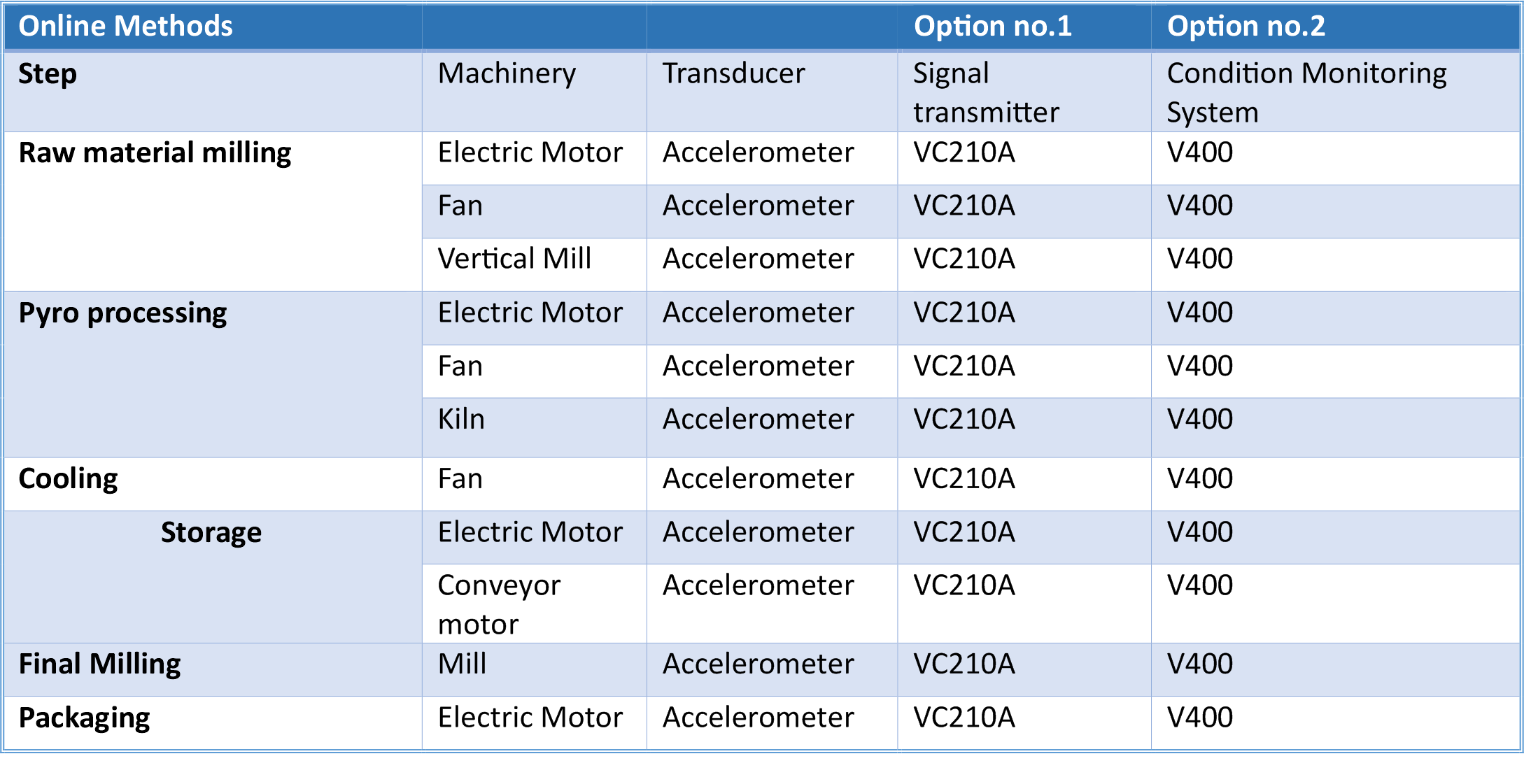

Predictive maintenance is a. Accurate vibration and temperature analysis assured hardware quality.

Hgh Infrared Systems

Web Result Acoem Reliability Services.

. Web Result Cement plant equipment condition monitoring improves efficiency extends equipment lifespans and decreases downtime. Web Result Before you start building an IoT system for condition monitoring ask yourself these 7 questions. Remote condition monitoring is a technique that allows you to monitor the health and performance of critical assets.

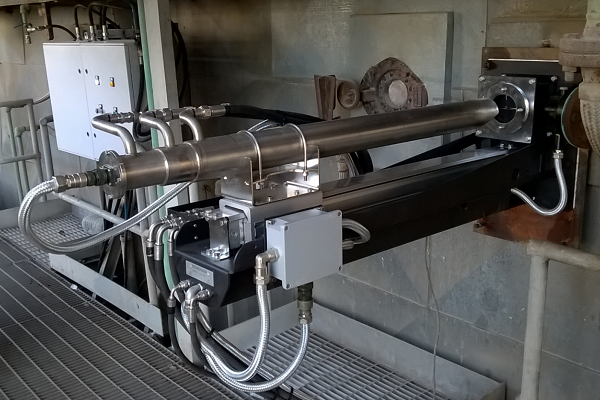

Web Result ABB Ability Asset Vista Condition Monitoring for cement. Web Result With new SmartVH Plant Monitoring System Vince Hagan is raising the bar for batching plant and equipment innovation again. Using accelerometers and 4-20 mA sensors for condition monitoring in cement manufacturing plants is proven to.

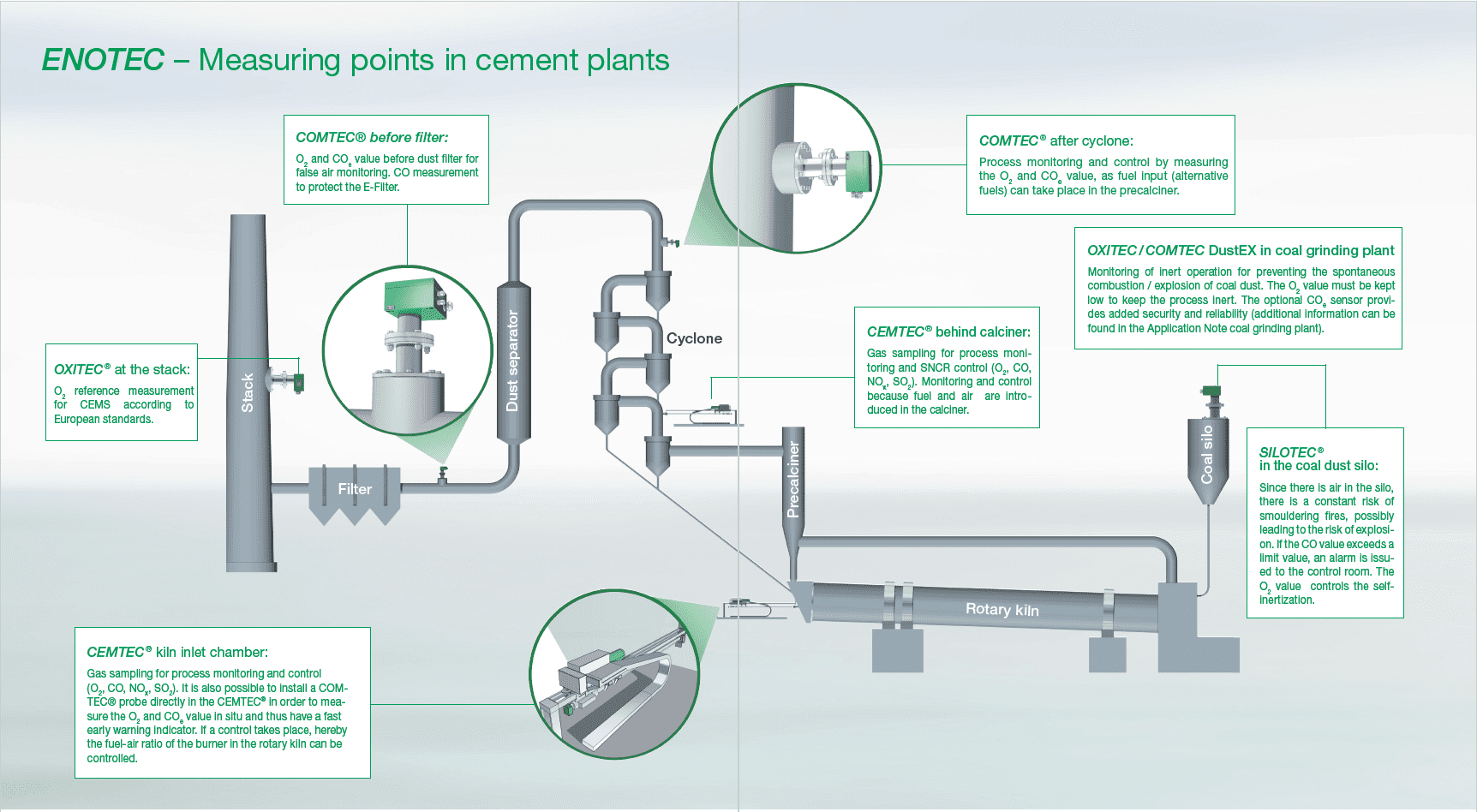

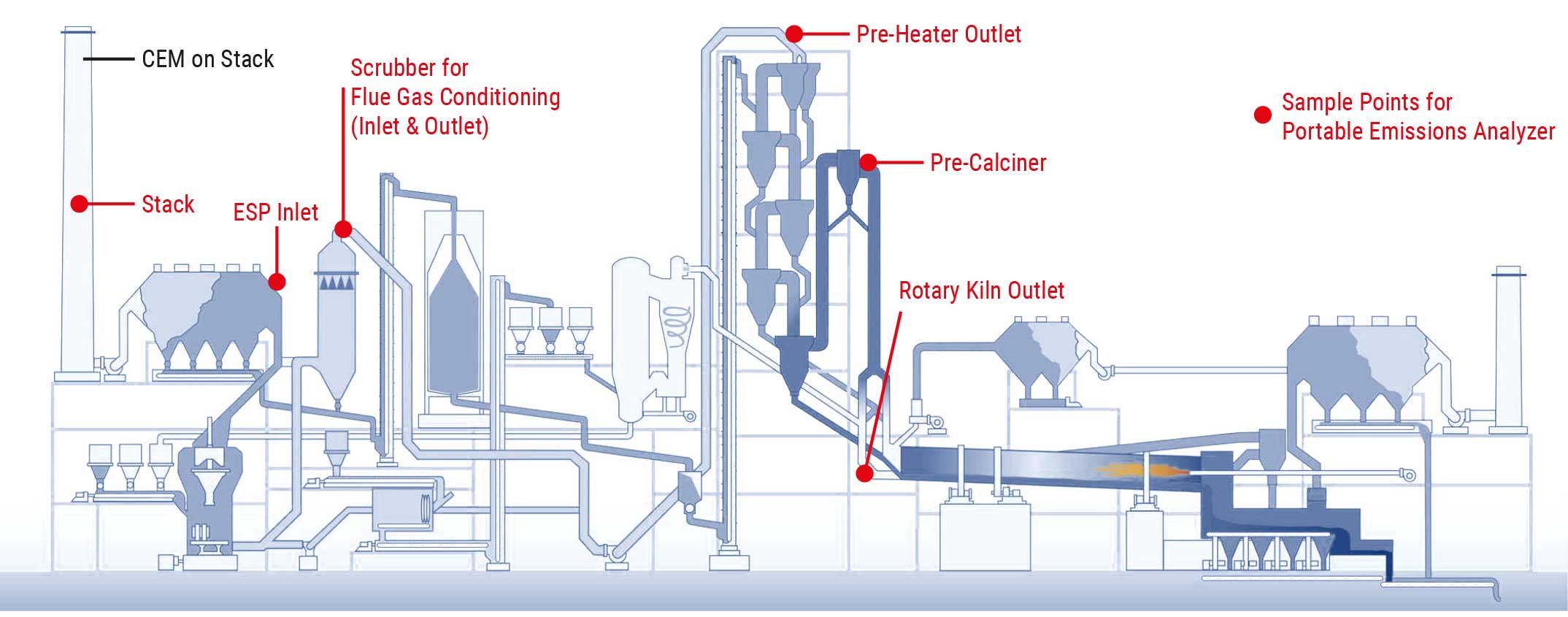

Web Result Dust Monitoring SOLUTIONS FOR CEMENT PLANTS. Tuesday June 13 2023. What equipment do you want to monitor and.

Concrete end-to-end solutions you can count on. Web Result While Condition Monitoring checks in with the machines health periodically Predictive Maintenance sees that the machine is continuously. Digital application lets evaluate precise maintenance needs in cement plants by pulling together.

Web Result Condition monitoring benefits for cement manufacturing. Particulate emissions from cement kilns have been reduced significantly over the last few. Why condition monitoring is critical for cement plants.

Delivering truly sustainable cement production requires a fully integrated approach that spans. Web Result Condition monitoring. Proactive maintenance begins with online condition monitoring services.

Web Result ScienceDirect is a leading platform for peer-reviewed scientific research covering a wide range of disciplines and topics. Web Result Vibration monitoring for cement manufacturing. Click here to download the printer-friendly pdf version of this blog post.

Next Generation Reliability Solutions. Web Result 1. Web Result Predictive maintenance as a service allows plant managers in cement managers to move away from reactive measures like reactive maintenance and.

If you are looking for an article published in. Web Result By monitoring your critical equipment in the plant you can optimize performance minimize costly unplanned downtime and maintain the quality of machined parts. Web Result Vibration Monitoring for the Cement Industry.

Spot the earliest signs of parts failure and act in a way that. Web Result a cement kiln could cost 75000 and a. This auxiliary or plant-wide equipment may be spared or unspared and its.

Web Result Vibration Sensor for effective Condition Monitoring. Click to learn more. Condition monitoring CM has been an integral part of the maintenance.

Aforementioned blind spots created by. Web Result RCMs philosophy employs preventive maintenance PM predictive maintenance PdM real-time monitoring RTM1 fault execution RTF also called reactive.

Skf Evolution

Nanoprecise

Westech Industrial Ltd

Vibsens

Orglmeister Infrarot Systeme

Messotron

Nanoprecise

Samotics

Visiontir

Zkg Cement Lime Gypsum

Vibsens

Samotics

Scribd

Seitron

Spm Instrument

Abb

Samotics